Last Updated: August 2025 | Reading Time: 12 minutes

Are you considering a modular wheelchair ramp for your home or business? This comprehensive guide covers everything you need to know about wheelchair ramp installation, costs, regulations, and maintenance requirements in the UK and USA.

What Are Modular Wheelchair Ramps?

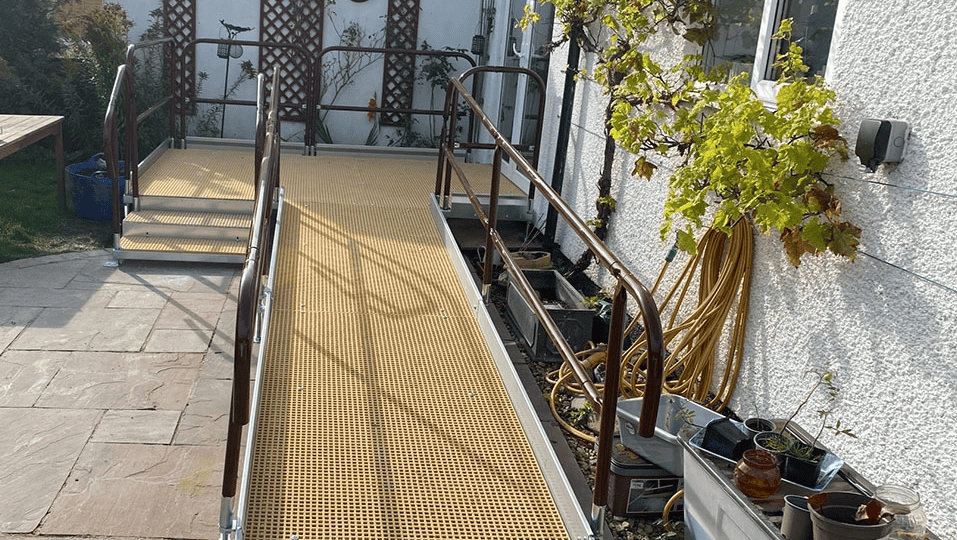

Modular wheelchair ramps (also known as disabled access ramps or mobility ramps) are pre-fabricated, adjustable ramp systems designed to provide safe access for wheelchair users and people with mobility challenges. Unlike permanent concrete ramps, modular systems can be:

- ✅ Easily relocated when you move home

- ✅ Quickly installed (often same-day)

- ✅ Customized to fit any property layout

- ✅ Cost-effective compared to permanent solutions

Is Your Property Suitable for a Modular Wheelchair Ramp?

✅ Ideal Properties Include:

- Residential homes with front/back door steps

- Care homes and assisted living facilities

- Small businesses requiring accessibility compliance

- Temporary venues needing portable access solutions

🏠 Key Property Requirements

Space Availability

Your property needs sufficient space to accommodate the ramp’s length. UK regulations (BS 8300) require:

- 1:20 gradient for outdoor ramps (1 meter length per 50mm rise)

- 1:12 gradient permitted for short ramps under 2 meters

- Minimum 1.5m width for comfortable wheelchair access

Ground Conditions

- Level, stable ground preferred

- Concrete, paving, or firm soil work best

- Adjustable leg systems available for uneven terrain

- Drainage considerations for wet weather areas

User-Specific Needs

Consider the wheelchair user’s requirements:

- Manual vs. electric wheelchair dimensions

- Caregiver assistance space requirements

- Frequency of use (daily vs. occasional)

- Weather protection needs

Professional Wheelchair Ramp Survey Process

📋 Initial Consultation (Free with Most Suppliers)

A qualified accessibility assessor will:

- Assess user mobility needs and wheelchair specifications

- Evaluate property layout and access points

- Discuss budget and timeline requirements

- Explain available options (straight, L-shaped, U-shaped ramps)

📏 Detailed Site Measurements

Professional surveyors measure:

- Step height and depth (crucial for gradient calculations)

- Available space for ramp placement

- Pathway widths and turning circles

- Potential obstacles (drainage, utilities, landscaping)

✅ Compliance Assessment

UK Building Regulations Check:

- Part M compliance (accessibility requirements)

- Planning permission requirements (if applicable)

- BS 8300 standards adherence

- Local council accessibility guidelines

UK vs USA Wheelchair Ramp Regulations

🇬🇧 UK vs USA Wheelchair Ramp Standards

| Requirement | UK (BS 8300) | USA (ADA) |

|---|---|---|

| Maximum Gradient | 1:20 (outdoor), 1:12 (short ramps <2m) | 1:12 (maximum slope) |

| Minimum Width | 1,500mm (1.5m) | 36 inches (914mm) |

| Handrail Height | 900-1,000mm above surface | 34-38 inches above surface |

| Landing Size | Minimum 1,500mm x 1,500mm | Minimum 60 inches x 60 inches |

| Surface Requirements | Slip-resistant, max 15mm gaps | Stable, firm, slip-resistant |

Modular Wheelchair Ramp Installation Process

⏱️ Installation Timeline

- Simple straight ramps: 2-4 hours

- Complex multi-platform systems: 1-2 days

- Weather-dependent (dry conditions preferred)

🔧 Step-by-Step Installation

1. Site Preparation (30-60 minutes)

- Clear installation area of debris

- Level ground where necessary

- Mark utility lines (gas, electric, water)

- Protect landscaping and property

2. Foundation Setup (1-2 hours)

- Install concrete pads or adjustable feet

- Ensure proper drainage around foundations

- Check levels using professional equipment

- Allow concrete to cure (if required)

3. Modular Assembly (2-4 hours)

- Connect pre-fabricated sections using galvanized bolts

- Install platform sections and turn platforms

- Ensure seamless joints between sections

- Test structural integrity at each stage

4. Safety Features Installation (1 hour)

- Mount handrails on both sides (regulations requirement)

- Apply anti-slip surface treatments

- Install edge protection barriers

- Add toe boards where required

5. Final Testing & Handover (30 minutes)

- Load testing with user’s wheelchair

- Safety demonstration for user and carers

- Maintenance schedule explanation

- Warranty documentation provided

Wheelchair Ramp Maintenance: Essential Tasks

📅 Monthly Inspections

Visual Checks:

- ✅ Handrail stability – check all fixings

- ✅ Surface condition – look for cracks or wear

- ✅ Drainage – ensure water runoff is clear

- ✅ Rust spots – treat immediately to prevent spread

🧹 Seasonal Maintenance

Spring Maintenance:

- Deep clean all surfaces with appropriate cleaners

- Re-apply anti-slip coating if worn

- Check expansion joints after winter freeze/thaw

- Lubricate moving parts (if applicable)

Winter Preparation:

- Install ice prevention systems where needed

- Stock de-icing materials (wheelchair-safe products only)

- Check drainage is working effectively

- Inspect for weather damage after storms

💰 Maintenance Costs

Annual maintenance budget:

- Basic cleaning supplies: £50-100

- Professional inspection: £150-300

- Minor repairs: £100-500

- Major component replacement: £500-1,500

Modular Wheelchair Ramp Costs UK

💷 Modular Wheelchair Ramp Prices UK (2025)

| Ramp Type | Length | Price Range |

|---|---|---|

| Straight Ramp | 2-4 meters | £1,500 – £3,500 |

| L-Shaped Ramp | 4-8 meters | £3,000 – £7,000 |

| Complex System | 8+ meters | £6,000 – £15,000+ |

Price includes: Professional survey, all materials, installation, 12-month warranty, basic maintenance kit

Price includes:

- Professional survey and design

- All materials and components

- Full installation service

- 12-month warranty

- Basic maintenance kit

💰 Funding Options

Grants Available:

- Disabled Facilities Grant (up to £30,000)

- Access to Work Scheme (business premises)

- Local council grants (varies by area)

- Charity funding (condition-specific organizations)

Choosing the Right Wheelchair Ramp Supplier

✅ What to Look For:

- BHTA membership (British Healthcare Trades Association)

- Minimum 5-year warranty on structure

- Professional design service included

- Local installation teams in your area

- Positive customer reviews and case studies

❓ Questions to Ask Suppliers:

- “Do you provide free surveys and quotes?”

- “What’s included in your warranty?”

- “Can you provide local customer references?”

- “Do you offer maintenance contracts?”

- “What’s your typical installation timeframe?”

Frequently Asked Questions

Do I need planning permission for a wheelchair ramp?

Most residential wheelchair ramps under 30cm high are permitted development and don’t require planning permission. However, listed buildings and conservation areas may have restrictions.

How long do modular wheelchair ramps last?

High-quality aluminum ramps typically last 15-25 years with proper maintenance. Galvanized steel systems can last 20-30 years.

Can modular ramps be relocated?

Yes! Modular systems can be disassembled and relocated when you move home, making them more cost-effective than permanent concrete ramps.

Are modular ramps suitable for all wheelchairs?

Modern modular ramps accommodate all wheelchair types including electric wheelchairs, mobility scooters, and assisted walking frames when properly designed.

Next Steps: Getting Your Wheelchair Ramp

🎯 Action Plan:

- 📞 Contact 3-5 local suppliers for free quotes

- 📋 Book professional surveys (usually free)

- 💰 Research available grants and funding

- 📝 Compare quotes including warranty terms

- ⚖️ Check supplier credentials and reviews

🔗 Useful Resources:

- Disabled Living Foundation: Equipment advice and funding guidance

- BHTA Directory: Find certified ramp suppliers

- Local Council: Disabled facilities grant information

- Access to Work: Business accessibility funding

Need more mobility advice? Join our community of 2,000+ members sharing practical tips on stairlifts, ramps, and accessibility solutions. Our expert members offer real-world advice on choosing the right mobility equipment for your needs.

💬 Join the discussion: Share your wheelchair ramp experiences or ask questions in our forum

This guide was written by mobility equipment specialists and reviewed by accessibility experts. Information is accurate as of August 2025. Always consult qualified professionals for specific installation requirements.

Related Articles: